AI camera for QR code reading

Automated logistics flow controlLoading errors and manual checks slow down your logistics flows and affect your profitability. That’s why we designed an automated control system powered by AI camera technology, built to make your dock operations faster and more reliable.

Designed for the most demanding environments, this robust equipment combines AI-based QR code recognition with automatic triggering through motion detection. It provides real-time traceability data, directly connected to your WMS or ERP, and ensures that the right product is always loaded into the right truck — without interrupting your operators’ work.

High-Performance AI Recognition Technology

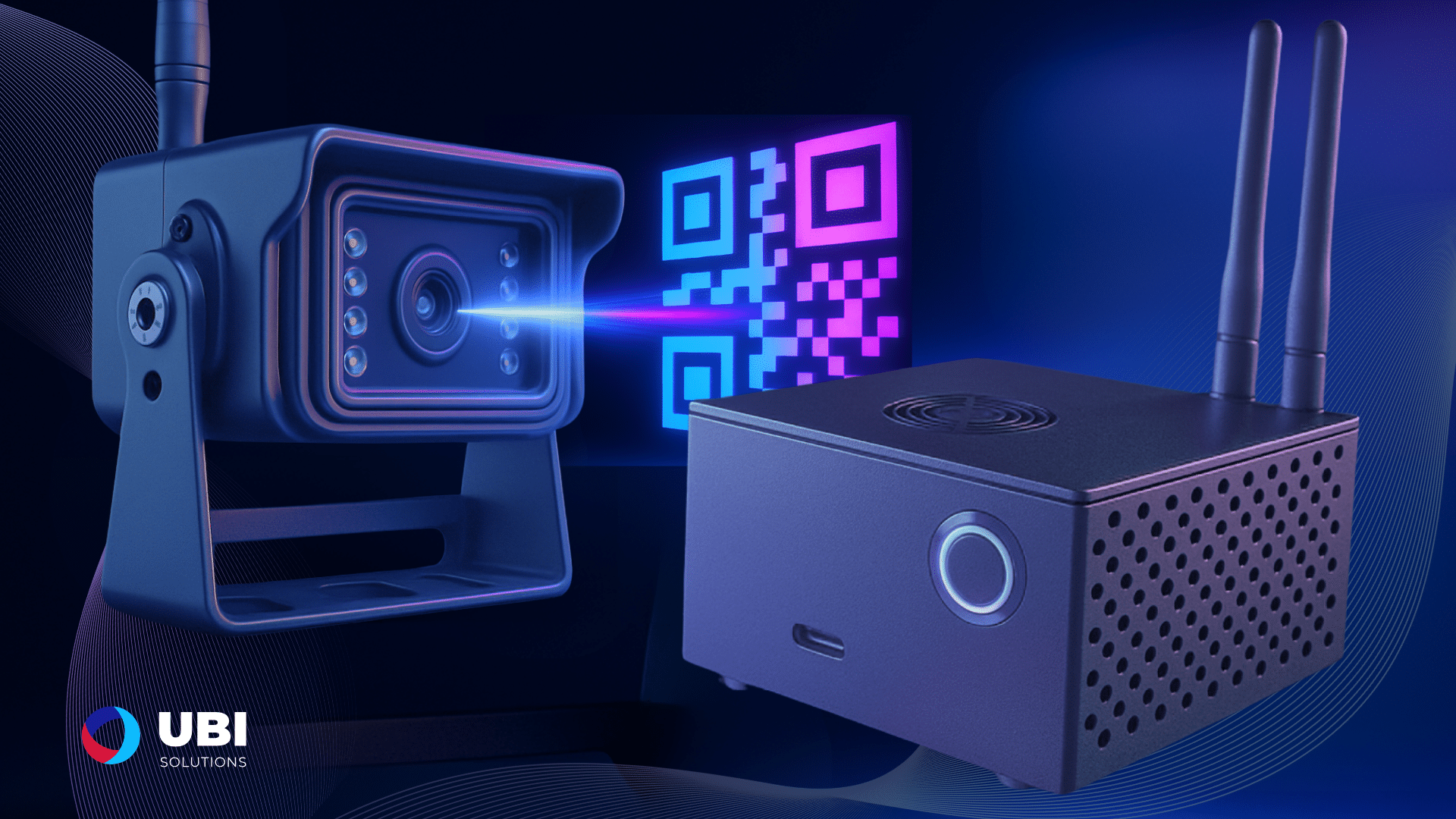

The system is built on a powerful architecture: one or more AI cameras are mounted on a gantry, while the intelligence is embedded in a central unit that processes all data.

✅ Instant Capture: QR codes placed on each pallet are automatically recognized through the video stream in less than 100 milliseconds.

✅ Automatic Triggering: Motion sensors activate the system as a forklift approaches, making the process 100% autonomous.

✅ Smart Validation: The AI verifies data consistency (pallet, destination, etc.) and records every movement in the system.

✅ WMS/ERP Interface: The technology is designed to integrate seamlessly with your warehouse management system (WMS) and other enterprise software for smooth data exchange.

A Complete and Robust Hardware System

Our technology is a comprehensive hardware and software ecosystem designed to integrate seamlessly into your environment.

✅ State-of-the-art gantry: A robust structure that perfectly positions the cameras and sensors for optimal capture.

✅ Smart AI cameras: High-resolution cameras capable of smooth and reliable reading, even in motion.

✅ Motion sensors: Ensure a fully automatic, hands-free triggering of the reading process.

✅ Warning light column: Provides real-time visual feedback to the operator on validation status (success or anomaly) through a simple light signal.

Tangible Benefits for Your Logistics Operations

Transform your dock operations into a measurable competitive advantage.

✅ Ensure 100% reliability of your loadings and receptions

Our system guarantees perfect matching between pallets and trucks, eliminating shipping errors and costly disputes.

✅ Speed up your dock flows

By removing manual stops and scans, you significantly reduce pallet processing time and increase daily rotation rates.

✅ Obtain indisputable visual proof

For every passage, the system provides video evidence of the loading process and pallet condition — a major asset for dispute management.

✅ Reduce manual interventions

The process is fully automated. Your operators can focus on their tasks without interruption, optimizing overall productivity.

✅ Automate your flow inventories

Since every entry and exit is digitally recorded, you gain a precise and automatic flow inventory, improving overall stock management.

Our solution has already proven its efficiency at Eaux Zilia, a well-known player in the mineral water industry. By automating and securing their dock operations, the company achieved smoother logistics, fewer loading errors, and stronger shipment traceability. The observed benefits are significant — both in operational performance and in peace of mind for their teams. Discover their full feedback in the video below.

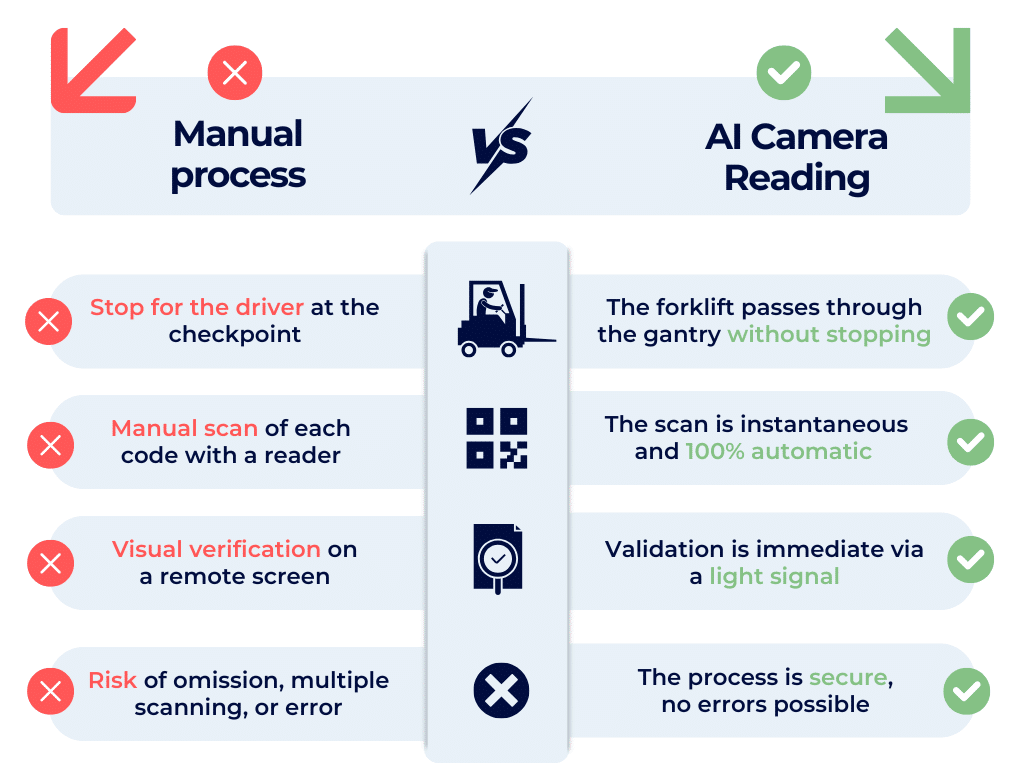

Manual Process vs. Automated Camera-Based Reading

Redefine the performance of your control points. Our integrated system replaces multiple devices and manual steps with one seamless operation.